A cost comparison between drilling glass with laser and water jet

#lasermeetsglass

Drilling glass is a precise and delicate process that requires specialized equipment. Two popular methods for drilling glass are using a laser or a water jet. Although both technologies have their advantages, a key factor that companies need to consider when choosing a technology is cost. In this article, we compare the costs of glass drilling with laser and waterjet. We divide the costs into two main components: the initial investment and the operating costs. By examining these costs, we hope to help companies make informed decisions about the most appropriate technology.

Initial investment:

The cost of a new machine can be divided into two main components. First comes the initial investment and then the operating costs.

The volume of the initial investment in these two examples is based on standard machines. However, prices can vary depending on the size and performance of the machine. The figures given here are an average cost estimate. Obviously, the laser machine starts with higher costs and almost no favorable models due to the high cost of the laser source. The water jet can offer cost-effective alternatives here.

Operating costs:

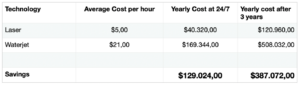

In terms of running costs, the laser machine offers an amazing advantage, averaging a stable $4 to $6 per hour (results may vary slightly depending on electricity prices in your country). 1/3 of these costs are attributable to electricity consumption (6.5 KVA), the rest to maintenance and repairs.

The least the waterjet can offer here is twice what the laser costs, $12 per hour, and depending on the use and size of the machine, it can be as much as $30 per hour.

A basic calculation of operating costs over 1 year shows the savings over time:

Although the initial investment with the laser option is high, the savings in operating costs after the third year are so great compared to the alternative that it is possible to buy a new machine with the savings.

In summary, when drilling glass, companies need to consider not only the processing time and initial investment of the technology, but also the overall cost. While a laser machine may have a higher initial investment, the lower operating costs over time can make it a more cost-effective option. On the other hand, a waterjet machine may offer more cost-effective options for the initial investment, but its operating costs are usually higher than those of a laser machine. Ultimately, companies should weigh up the pros and cons of each technology and consider their specific requirements before making a decision. With this cost comparison between laser and waterjet glass drilling, we hope to have provided valuable insights to help companies make an informed decision.

If you would like more detailed answers on this topic or related topics in connection with our laser technology, please do not hesitate to contact us.