The Future of Vacuum Insulating Glass and the Role of Laser Glass Drilling

As energy efficiency and sustainable building solutions become increasingly important, vacuum insulating glass (VIG) is gaining traction as a cutting-edge solution in the glass industry. VIG consists of two glass panes separated by a vacuum layer, which significantly reduces heat transfer and enhances thermal insulation. This makes it an ideal choice for energy-efficient buildings, high-performance windows, and even specialized industrial applications.

Why Vacuum Insulating Glass Matters

Traditional insulating glass units rely on gas fillings like argon or krypton to minimize heat transfer. However, over time, these gases can slowly escape, reducing the effectiveness of the insulation. VIG, on the other hand, leverages a vacuum—a perfect insulator—to achieve superior thermal performance while maintaining a slim and lightweight structure. With increasing global regulations for energy efficiency, VIG is set to play a crucial role in modern construction and design.

The Challenges of Drilling Holes in VIG

One of the key challenges in producing vacuum insulating glass is the precise drilling of holes. These holes are necessary for evacuating air from between the panes and ensuring a long-lasting vacuum seal. However, traditional drilling methods often introduce stress into the glass, increasing the risk of breakage. Additionally, conventional mechanical drilling methods struggle with producing the specialized hole shapes required for proper sealing and adhesion.

Why Laser Technology is the Ideal Solution

At MDI Advanced Processing, we have been providing laser drilling solutions for the glass industry, and we are seeing growing demand for our technology in VIG production. Our laser technology offers a range of advantages specifically suited to the requirements of VIG manufacturers:

Precision Drilling: Our laser systems can drill extremely small and highly precise holes, ensuring minimal material disruption while maintaining the integrity of the glass.

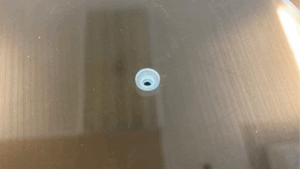

Specialized Hole Shapes: Unlike traditional drilling methods, lasers can create conic shapes or sinkholes, which improve the bonding of glass pieces and enhance overall product quality.

Edge Proximity: Our laser technology allows for the drilling of holes close to the edges of the glass without the risk of cracking, giving manufacturers greater design flexibility.

Improved Adhesion: The laser process creates a rough surface inside the drilled holes, which significantly enhances glue adhesion and improves long-term durability.

Meeting Industry Demands

As demand for vacuum insulating glass continues to rise, manufacturers are looking for innovative ways to optimize their production processes. Our laser drilling technology offers a clean, efficient, and precise method for creating the necessary holes in VIG while reducing waste and minimizing glass breakage.

If you are in the glass industry and looking for advanced solutions to improve your VIG production, we invite you to explore the benefits of laser drilling. Contact us to learn more about how our technology can enhance your manufacturing process and help you stay ahead in this rapidly evolving market.